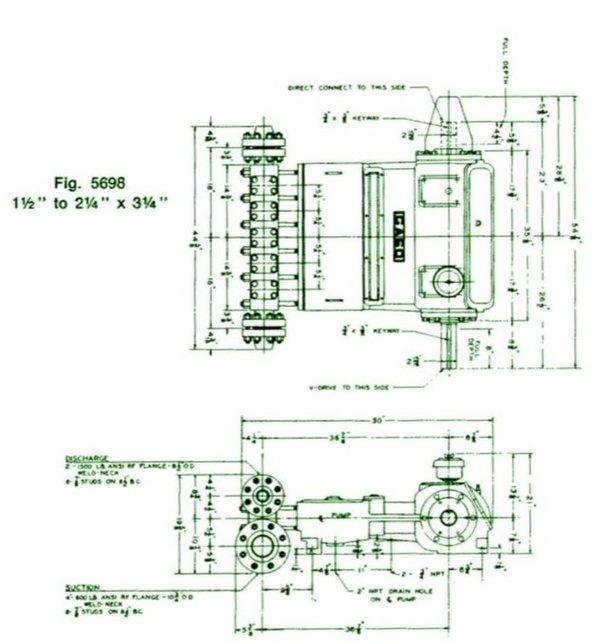

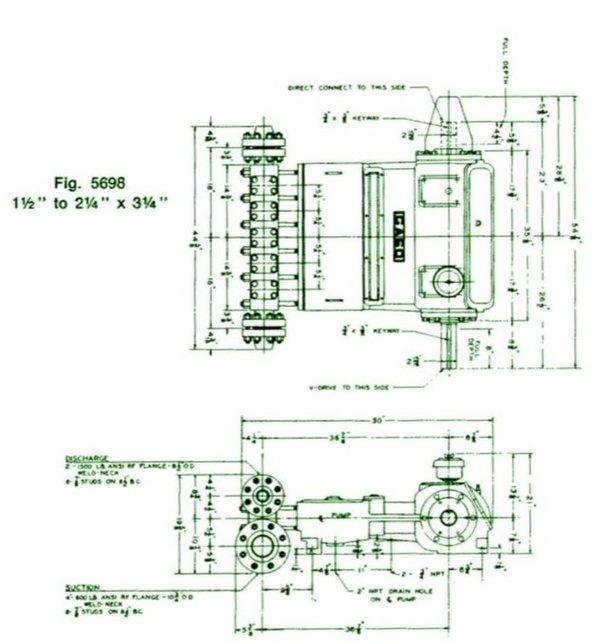

Gaso, 5698-M, Quintuplex, Plunger Pump

Specs

| Spec | U.S. Standard |

|---|---|

| Type: | quintuplex |

| Minimum Plunger Diameter: | 1½" |

| Maximum Plunger Diameter: | 2¼" |

| Stroke length: | 3½" |

| Maximum Working Pressure: | 2,900 PSI |

| Rod/Piston Load: | 5130lb |

| Gallons per Minute: | 150.0 |

| Barrels per Day: | 5143 |

| Brake Horse Power: | 125.0 |

Mouse-over to Enlarge

Hover over Power Curves to reveal RPM and GPM

| Pump | English Units | 50 RPM | 200 RPM | 350 RPM | 500 RPM | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plunger Dia. In. | Plunger Area Sq. In. | BPD per RPM | GPM per RPM | Max Press. PSI | BPD | GPM | BPD | GPM | BPD | GPM | BPD | GPM | |

| 5698-M | 2.250 | 3.9761 | 10.327 | 0.3012 | 1290 | 516 | 15 | 2066 | 60 | 3615 | 105 | 5164 | 151 |

| 2.125 | 3.5466 | 9.212 | 0.2687 | 1446 | 461 | 13 | 1842 | 54 | 3224 | 94 | 4606 | 134 | |

| 2.000 | 3.1416 | 8.160 | 0.2380 | 1633 | 408 | 12 | 1632 | 48 | 2856 | 83 | 4080 | 119 | |

| 1.875 | 2.7612 | 7.172 | 0.2092 | 1858 | 359 | 10 | 1434 | 42 | 2510 | 73 | 3586 | 105 | |

| 1.750 | 2.4053 | 6.247 | 0.1822 | 2133 | 312 | 9 | 1250 | 36 | 2187 | 64 | 3124 | 91 | |

| 1.625 | 2.0739 | 5.387 | 0.1571 | 2474 | 269 | 8 | 1077 | 31 | 1885 | 55 | 2693 | 79 | |

| 1.500 | 1.7671 | 4.590 | 0.1339 | 2900 | 229 | 7 | 918 | 27 | 1607 | 47 | 2295 | 67 | |

Ratings published here in are intended to be used only for preliminary planning purposes, and as such carried no warranties whatsoever. All applications for gas opines must be approved in writing. THE INFORMATION CONTAINED HERE IS TRANSCRIBED FROM A GASO TECHNICAL MANUAL FROMM THE 1960âS - 70âS. IEQ INDUSTRIES OR THE CUSTODIANS OF THIS WEBSITE ARE NOT RESPONSIBLE FOR ITS CONTENT.

GASO pumps are engineered to deliver the book plus values which have distinguished GASO pumps for over 60 years and to provide longer life and lower maintenance costs. Important design features include:

Power Frame. High-strength gray iron alloy casting with heavy wall sections well written to ensure rigid construction.

Crankshaft. Mounted with centerline of shaft on centerline of cross heads. Crankshaft may extend from either side of the pump.

Crankshaft Bearings. Interchangeable heavy-duty roller bearings.

Connecting Rods. Connecting rods have renewable Babbit lined steel backed shell bearings at the crank end and bronze bushings at crosshead end.

Crossheads. Cross head tends are hardened and ground steel.

Lubrication. All power and parts are lubricated by splash system from oil in the crankcase reservoir. Power frame has an oil return channel, from front of the cross heads back to the crankcase, to permit constant circulation of oil and to help keep oil cool.

FLUID END BODY. Alloys which are stocked our Molybnenum alloy iron for crude oil and freshwater service, and steel for pumping petroleum products in hazardous locations. Aluminum bronze alloys are used for salt water and other corrosive liquids. Special alloys such as Hastalloy C, Inconel or stainless steel can be furnished upon request.

PLUNGERS. Plunger materials are available in: file hard steel,colmonoy's surfaced steel, solid ceramic, and chrome plated steel.

PACKING. Standard packing is a set of non-crushable lid tight packing rings. Other packing can be furnished for special applications.

PlLUNGER LUBRICATION. Furnished by use of grip oilers or regulated flow of oil from a force-feed's lubricator. Lubricate or is mounted on the pump with separate oil lines to each plunger.