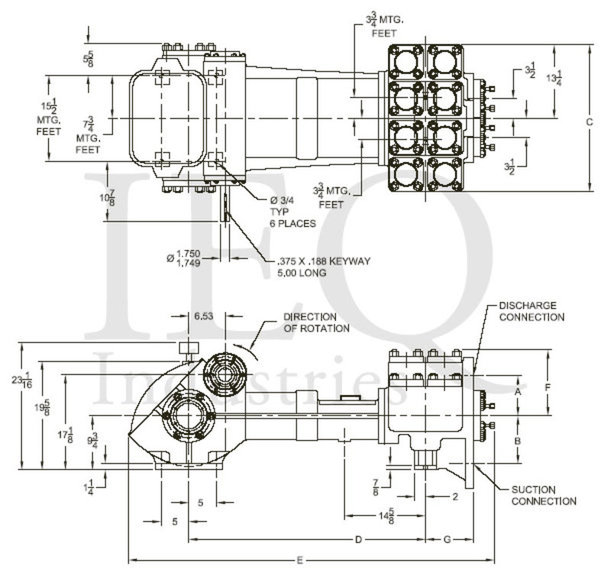

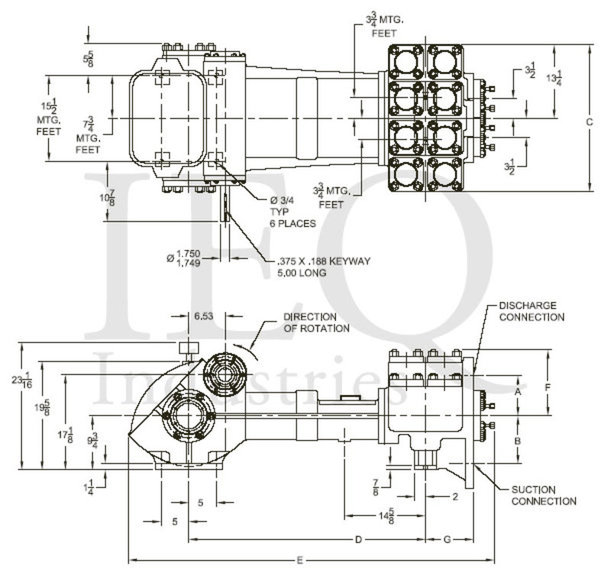

Gaso, 1845, Duplex, Piston Pump (Mud Pump)

Specs

| Spec | U.S. Standard |

|---|---|

| Type: | duplex |

| Minimum Piston Diameter: | 5" |

| Maximum Piston Diameter: | 6" |

| Stroke length: | 6" |

| Maximum Working Pressure: | 240 PSI |

| Rod/Piston Load: | 4850lb |

| Gallons per Minute: | 260.0 |

| Barrels per Day: | 8914 |

| Brake Horse Power: | 28.0 |

Mouse-over to Enlarge

Hover over Power Curves to reveal RPM and GPM

| Pump | English Units | 50 RPM | 60 RPM | 70 RPM | 80 RPM | 85 RPM | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plunger Dia. In. | Plunger Area Sq. In. | BPD per RPM | GPM per RPM | Max Press. PSI | BPD | GPM | BPD | GPM | BPD | GPM | BPD | GPM | BPD | GPM | |

| 1845 | 6.000 | 28.2743 | 100.717 | 2.9376 | 172 | 5036 | 147 | 6043 | 176 | 7050 | 206 | 8057 | 235 | 8561 | 250 |

| 5.875 | 27.1085 | 96.565 | 2.8165 | 179 | 4828 | 141 | 5794 | 169 | 6760 | 197 | 7725 | 225 | 8208 | 239 | |

| 5.750 | 25.9672 | 92.499 | 2.6979 | 187 | 4625 | 135 | 5550 | 162 | 6475 | 189 | 7400 | 216 | 7862 | 229 | |

| 5.625 | 24.8505 | 88.521 | 2.5819 | 195 | 4426 | 129 | 5311 | 155 | 6197 | 181 | 7082 | 207 | 7524 | 219 | |

| 5.500 | 23.7583 | 84.631 | 2.4684 | 204 | 4232 | 123 | 5078 | 148 | 5924 | 173 | 6771 | 197 | 7194 | 210 | |

| 5.375 | 22.6906 | 80.828 | 2.3575 | 214 | 4041 | 118 | 4850 | 141 | 5658 | 165 | 6466 | 189 | 6870 | 200 | |

| 5.250 | 21.6475 | 77.112 | 2.2491 | 224 | 3856 | 112 | 4627 | 135 | 5398 | 157 | 6169 | 180 | 6555 | 191 | |

| 5.125 | 20.6290 | 73.484 | 2.1433 | 235 | 3674 | 107 | 4409 | 129 | 5144 | 150 | 5879 | 171 | 6246 | 182 | |

| 5.000 | 19.6350 | 69.943 | 2.0400 | 240 | 3497 | 102 | 4197 | 122 | 4896 | 143 | 5595 | 163 | 5945 | 173 | |

Ratings published here in are intended to be used only for preliminary planning purposes, and as such carried no warranties whatsoever. All applications for gas opines must be approved in writing. THE INFORMATION CONTAINED HERE IS TRANSCRIBED FROM A GASO TECHNICAL MANUAL FROM THE 1960âS - 70âS. IEQ INDUSTRIES OR THE CUSTODIANS OF THIS WEBSITE ARE NOT RESPONSIBLE FOR ITS CONTENT.

Power Frame. High-strength gray iron alloy casting with heavy wall sections, well ribbed to ensure rigid construction and design to fully enclose all working parts.

Gears. Continuous to Sykes herringbone construction. Main gear is heat treated high-grade ductile iron. Pinion gear is cut from forged alloy steel and hardened.

Crankshaft. Have a center section for mounting main gear. Large diameter crank pins

Pinion Shaft. Alloy steel bar stock, machine and precision ground.

Bearings. Heavy duty tapered roller bearings on crankshaft. Self-contained double roll bearings on pinion shaft to permit free floating of shaft for self centering of peers.

Connecting Rods. Heavy cross section castings with renewable Babbitt lined steel shell bearings and crank and; bronze bushing in cross head end.

Lubrication. All power and parts including gears, cross heads, connecting rod bearings, crankshaft bearings and pinion crank shaft bearings, are lubricated by splash system from lubricant in crankcase reservoir.

Power Frame. Alloys stocked are Molybdenumâs cast iron and cast steel. Fluid ounce can be trimmed out for pumping various liquids. Ductile iron can be furnished upon request.

Cylinder Heads. Heavy section alloy casting to match material of pump fluid body.

Valve Covers. Heavy section alloy casting to match material of pump fluid body.

Liners. All pumps are available with interchangeable pipe liners. Standard materials available are Molybdenums alloyed iron, file hard steel and special corrosion resistant liners.

Piston Rods. Various rod materials are available. These are: steel, bronze, stainless steel, file hard steel, and chrome plated steel.

Pistons. Mollyâiron and bronze bodies fitted with various types of rings or cups are available.slush service pistons can also be furnished.

Valves. Valves and seats are available as follows: hardened and ground steel wing guided, bronze wing guided, steal or bronze insert type, direct blood valves for use on cast iron or bronze seats. McClatchie and mission can also be furnished.

Stuffing Boxes. All duplex pumps are furnished with replaceable type stuffing boxes which are available in cast iron and bronze.

Packing. Standard packing is a set of lipâtype packing rings. Other packings can be furnished for special applications.

Stuffing Box Lubrication. Furnished by use of regulated flow of oil from a force-feed lubricate or mounted on the pump, with a separate oil line to each stuffing box.